KOYO bearings need to add grease at any time to replace the grease that has deteriorated, exuded and contaminated. Due to the ever-changing operating conditions of KOYO bearings, on-site proprietary technology is required to determine the appropriate grease addition interval from once a day to once a year. There is no grease or grease addition plan that can take care of all the load, speed, and operating temperature conditions where a bearing exhibits excellent performance.

1. How long is the proper frequency of grease addition?

Unfortunately, there is no single answer, because there are many factors that affect the frequency of grease addition. Generally speaking, the smaller the bearing and the faster the speed, the lower the frequency of grease addition. Bearings with larger specifications and slower speeds need to be greased more frequently. The main factors are as follows:

Different types of bearings require different grease frequency:

Radial ball bearing = basic frequency.

Cylindrical roller bearings = 5 times the fundamental frequency.

Thrust rollers and roller bearings = operating temperature 10 times the fundamental frequency.

Higher temperature increases the oxidation rate of grease. When it exceeds 150°F (65°C), every 18°F (10°C) increase, the oxidation rate of grease doubles. For example: a bearing operating at 250°F (120°C); compared with a bearing operating at 150°F (65°C), the frequency of grease addition for the former is usually 10 times that of the latter.

In addition, as the temperature increases, the grease begins to soften, and may become fluid and leak out of the bearing housing.

High temperature operation requires a higher frequency of grease addition; high temperature grease can reduce this frequency.

Environmental conditions: If the bearing is operating in a polluted environment, the frequency of grease addition needs to be increased.

Make sure to point out any abnormal conditions in the lubrication report, such as high temperature, noise, vibration or leakage in the bearing.

2. Add grease at the flush interval

Many KOYO bearings require a small amount of grease to be added between grease flushing intervals. It is best to use a low-pressure grease gun to add grease. If the seal is in good condition, the amount and frequency of grease injection should be reduced.

(1) Check the grease inventory in KOYO bearings-remove the pipe fittings or grease drain plug, and check if there is excess grease flowing out.

(2) Check the KOYO bearing and seal for excessive leakage.

(3) Several "injections" are sufficient for each fatliquoring. Do not add too much grease!

3. Grease flushing

Regarding grease flushing, the following "decompression" methods are recommended.

For bearings equipped with pipe fittings and oil drain holes:

(1) Remove the lower oil drain plug; clean out all hardened grease.

(2) Clean the grease pipe fittings.

(3) Pump grease into the pipe until the old grease is completely replaced and new grease appears. Under safe and feasible conditions, it is best to be able to run the machine while performing this task.

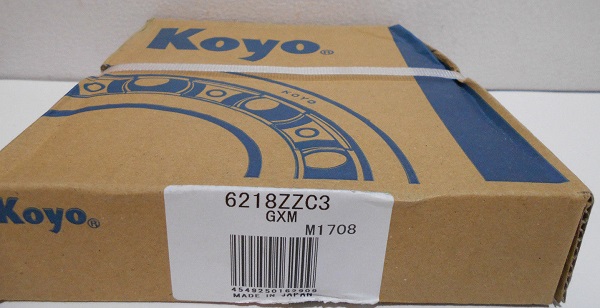

(4) While removing the oil drain plug, allow the machine to run at operating temperature. In this way, the grease can be evenly distributed and the excess grease can be squeezed out through the oil drain orifice, thereby releasing the internal pressure. When the normal pressure in the bearing box is reached (about 10-30 minutes), the excess grease will stop draining. KOYO 6218ZZC3 bearings online , pls click here :

4. Clean and replace the drain plug

For bearings with pipe fittings but no oil drain holes:

(1) Under safe conditions, remove the pipe fittings while the equipment is running at operating temperature to ensure that all excess grease in the bearing is discharged.

(2) Clean and replace pipe fittings. Pump a small amount of grease into the bearing to avoid breaking the grease seal.

(3) Remove the pipe fittings and allow the equipment to run at its operating temperature for several minutes to drain excess grease. If there is no grease discharge, the KOYO bearing is likely to be very dry, you need to repeat steps 2 and 3 until the excess grease is discharged.

(4) Replace the grease fittings.

For bearings equipped with pressure-reducing fittings but without oil drain holes:

(1) Clean the pipe fittings and pump grease into the bearing until the grease flows out from the pressure relief pipe fittings.

(2) If the grease does not flow out of the pressure relief pipe after injecting a large amount of grease, the pressure relief groove may be blocked. Remove the pressure relief pipe fittings and clean the pressure relief tank or replace with new pipe fittings. After cleaning or replacing the pipe fittings, repeat step 1.

(3) Run the equipment at operating temperature and check whether there is excess grease flowing out of the pressure reducing pipe.

5. Preventive measures

Make sure to clean up all excess grease and dust from the KOYO bearing and its surroundings. Excess grease and dust on the outer surface have a heat preservation effect and prevent heat dissipation. In addition, excess grease on the outer surface of the equipment and the ground can cause safety hazards to people.

For hard soap deposits, flush the bearing box with hot oil from the grease gun. Make sure to replace all the old oil in the bearing with new grease before operation.

It is impractical to flush out all the grease in large KOYO bearings, such as paper machine bearings. Please determine the amount of bearing grease added according to the manufacturer's instructions.

Please pay attention to the "danger signals" of abnormal bearing operation, such as abnormal noise, vibration and temperature. Making sure to pay more attention to these signs will go a long way in maintaining normal operations. The working condition monitoring instrument can be used to assist in detecting the bad working condition of the local bearing.

Hot Tags: