For several decades, Schaeffler has been offering a comprehensive portfolio for industrial robotics based on conventional bearing components such as radial and angular contact ball bearings, cylindrical roller bearings, tapered and spherical roller bearings etc. Over the years, special developments that are matched to suit articulated robots have been added, such as crossed roller bearings with and without gear teeth or angular contact roller bearings.

Applications

Bearing solutions and dynamic motion systems for robot-based automation

Today, smaller robots and some collaborative robots, so-called cobots, are being increasingly used for the automation of monotonous handling and assembly tasks, for dispensing adhesives and sealants or also for interlinking machines.

Their very slender articulated arms and relatively large working range result in large lever ratios between the load and bearing support or the load and the gear for the articulated arm. The loads also act over large distances on the linear bearing supports of the linear systems used as range extenders. As a result, bearing supports with particularly high rigidity and a high load carrying capacity are required – despite the comparatively low loads. The development of further applications for lightweight robot construction requires larger load carrying capacities within the same design envelope. To take account of these market dynamics, Schaeffler is presenting some new developments that will each set new benchmarks under its label Cobot Solutions. Schaeffler robot bearings online , pls click here :

Products

New bearing supports for lightweight robot construction

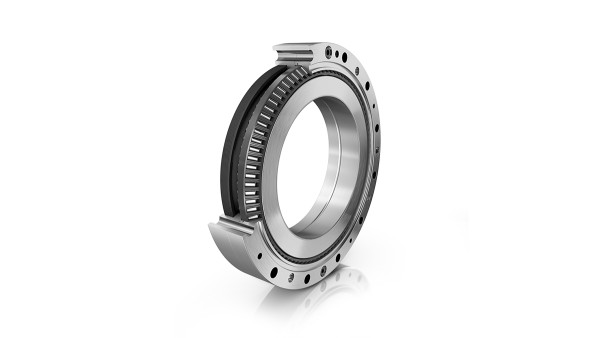

Schaeffler has developed a completely new bearing type specially for the articulated arms of lightweight robots (LBR) and cobots: The double-row XZU-series angular contact needle roller bearing. With a large number of rolling elements, rigid line contact, and an internal support distance provided by two separate raceways, XZU bearings offer optimum values with up to 30% more tilting rigidity and 20% less friction in comparison with crossed roller bearings of the same size. The optimized cage design offers lubricant pockets, which retain the lubricant in the rolling contact in an optimum manner. Apart from the reduced friction, this also leads to improved and more reliable sealing of the bearings.

Robot manufacturers can now design even smaller, lighter and more rigid articulated arms by using the new XZU angular contact needle roller bearings in lightweight robots. The advantages for the operator: The oscillation of the robot arms is significantly reduced and the control rigidity is improved.

New precision strain wave gears for lightweight robot construction

The RTWH-series DuraWave strain wave gear was also developed with the same objective. A major leap forward in development is required in order to be successful in a market with proven designs and experienced suppliers. For this reason, Schaeffler does not only use the new XZU angular contact needle roller bearings in DuraWave strain wave gears. The company also transferred its expertise in forming high strength gear teeth for the automotive market to the industrial sector. The precision strain wave gears are characterized by freedom from clearance, high positional accuracy, a compact design, and a very long operating life. RTWH DuraWave strain wave gears are currently offered in the four sizes 14, 17, 25, and 32 with gear ratios of 100 to 160 and nominal torques of 25 to almost 900 Nm.

UPRS PCB motor for cobots

The UPRS PCB motor represents the logical further development of drive technology for future-oriented, compact and dynamic drives for cobots. With a weight saving of up to 23% and an overall length reduction of 27%, it offers an increase in performance density of up to 59% compared with motors of a similar diameter and an overall increase in power density of up to 189%. This means that smaller and more powerful drives for robots are possible with the UPRS PCB motor from Schaeffler. In addition to excellent heat dissipation, a cogging torque of almost 0 (zero cogging) was achieved through optimizations in the motor design.

The motor will be available at the beginning of 2022, initially in the four sizes 14, 17, 25, and 32. These motors are optimized to suit the precision strain wave gears from Schaeffler but can also be installed separately.

Hot Tags: