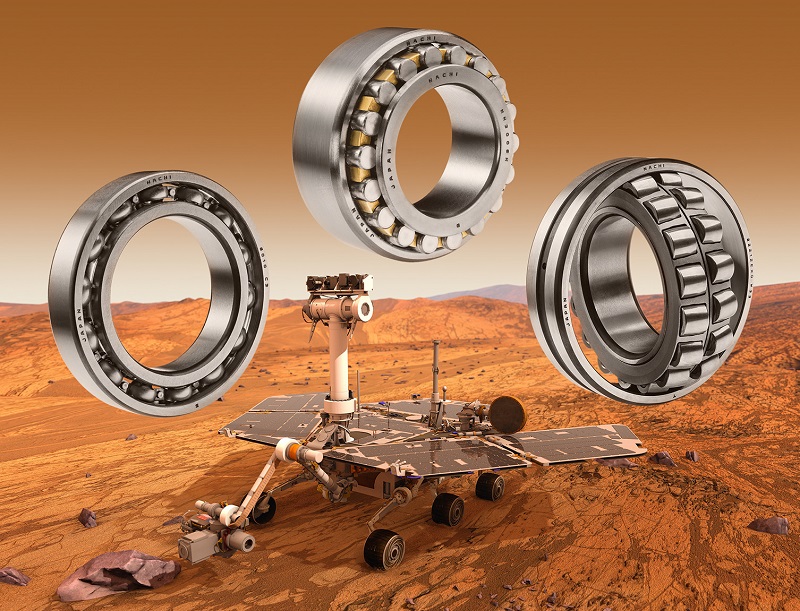

The choice of NACHI bearing type should be based on the type of load (radial, axial, torque) and the size of the load acting on the bearing. In the same size series of bearings, roller bearings have a greater load rating than ball bearings. NACHI Bearings online ,Click here

Spinning speed

The ultimate speed of a bearing depends on the bearing type, bearing size, working accuracy, cage structure, load, lubrication system, and seal type and design. The speed limit of the standard bearing given in the bearing size table is used as a basis for bearing type selection.

Noise and torque

All NACHI rolling bearings are designed and produced for operation with low noise and low torque. Among many types of ball and roller bearings, single row deep groove ball bearings are expected to operate with the lowest noise and torque.

Adjustment

If the adjustment accuracy of the shaft and bearing housing is inferior or the shaft deflects due to load, then the inner and outer rings of the bearing are eccentric.

Non-aligning rolling bearings can only control the allowable eccentricity through the combined internal clearance. If the desired angle of inclination occurs between the inner and outer rings, the bearing should be selected from types such as thrust ball bearings with spherical washers, spherical ball bearings or spherical roller bearings.The allowable tilt angle of the bearing varies with bearing type, internal clearance and load conditions.

Stiffness

When the rolling bearing is loaded, the contact area between the bearing ring and the rolling element will be elastically deformed. The amount of this elastic deformation will vary depending on the load, bearing type and bearing size. If comparing bearings of the same size series, roller bearings have much higher stiffness than ball bearings; comparing bearings of the same type, large size bearings have higher rigidity than smaller size bearings (two or more The preload assembly of the bearing assembly will increase the stiffness).

Install and disassemble

Rolling bearings are divided into separable or non-separable bearings. If a separable bearing is used, its installation and disassembly are very convenient. With the use of tapered bore bearings and bushings, or hydraulic devices, the installation and removal of bearings can be made easier.

Poor bearing installation may produce bearing noise and shorten life. Pay attention to the following when installing the bearing.

--Keep bearings clean

--Prevent corrosion

--Protect bearings from trauma

Axial positioning, bearing configuration

The shaft is usually supported by two (or equivalent) bearing units. Generally speaking, one of the bearings is to maintain (or fix) the axial position of the combination, and the other bearing is to allow linear expansion. The fixed-end bearing must be firmly installed on the bearing seat and the shaft.

Bearing environment

If there is a relatively large vibration source close to the bearing installation, or the bearing has to deal with impact loads, it is recommended to use spherical roller bearings or thrust spherical roller bearings. Standard bearings are not suitable for working under severe conditions (load, speed, operating temperature, amount of lubricant, vibration environment).

Hot Tags: