The so-called burn damage state of the NSK bearing refers to: the raceway wheel, rolling body and cage of the bearing heat rapidly during rotation until they become discolored, softened, welded, and damaged. The main cause of NSK bearing burns is due to the poor lubrication of the bearings, which may be the use of irregular lubricants, or too much or too little lubricant, which is not correct.

The second may be excessive load (excessive preload). The speed is too large. The play is too small. Water or other foreign objects invaded. If neither of the above two cases is true, then the shaft and bearing housing have poor accuracy and the shaft has a large deflection.First of all, we must study the lubricant and lubrication method, choose the bearing lubricant, and its amount, and correct the choice of bearing. Research should be to match, bearing clearance and preload, and improve the sealing device. Check the accuracy of the shaft and bearing housing.

It is recommended that when using NSK bearings, attention should be paid to the installation, lubrication, clearance and other links to be as accurate as possible and in place.

The general NSK bearing fatigue life refers to the rolling bearing under a certain technical state (structure, process state, fit, installation, clearance and lubrication state, etc.), which runs under the actual use state of the host until the rolling surface is fatigued and cannot be satisfied The total value of the relative rotation times of the bearing inner and outer rings (shaft, seat ring) when required by the host machine-the total number of revolutions.

When the bearing rotation is more or less constant or known, the fatigue life can be expressed by the total number of operating hours corresponding to the total number of rotations. In addition, it should also be noted that:

1. There are many factors that affect the fatigue life of NSK bearings, which cannot be fully estimated or eliminated through standard test conditions. This causes the actual fatigue life of NSK bearings to be very discrete, so the expression parameter of bearing fatigue life is the rated life L10 , The meaning of L10 in the ISO recommended standard R281 is clearly defined as follows:

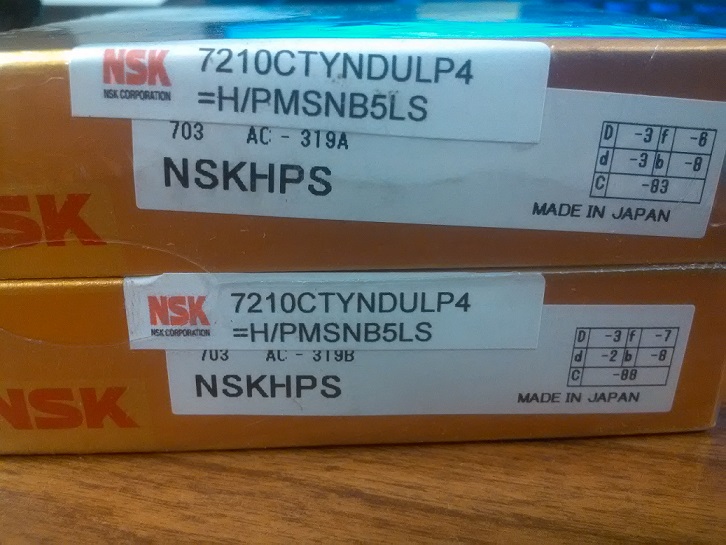

"The same batch of bearings in sufficient quantity, the rated life L10 is expressed in revolutions (or hours when the speed is constant, 90% of the bearings in the batch can reach or exceed this revolution before fatigue spalling occurs) Number (or hours)". So far, all countries in the world have complied with the above regulations. NSK 7210 CTYNDULP4 bearings online , pls click here :

In some countries such as the United States, the concept of median life is also used. The median life LM refers to the median life of a batch of identical NSK bearings, that is, 50% of the NSK bearings can reach or exceed the total number of revolutions before fatigue spalling, or the number of working hours at a certain speed, the median life LM It is not the arithmetic mean of the life of a batch of bearings. The general median life LM is about 5 times the rated life.

2. The concept of rated life only applies to a sufficient number of NSK bearings, but not to individual NSK bearings.

For example, there are 40 sets of 6204 bearings with a rated life of 1000h according to their use bar without fatigue damage, and the remaining 4 sets may have fatigue failure bearings within 1000h. The meaning of rated fatigue life means that these bearings are in normal condition The expected lifetime when the material's potential is fulfilled.

Therefore, in most cases, the user still makes the fatigue life calculation when selecting the bearing, and then performs the verification according to the actual failure category, such as wear life verification, and the smaller value in the calculation result is the calculated bearing life.

Conditions for judging whether NSK bearings need to be replaced

NSK imported bearings are not used for a long time, so the frequency of damage is relatively high, so after a short time, they must be replaced once, so as not to cause unnecessary losses, but under what circumstances, the bearings need to be replaced, how should we To determine whether the bearing is available? It is mainly determined by considering the degree of bearing damage, mechanical properties, importance, operating conditions, and the period until the next maintenance. If there are the following defects, they can no longer be used, and new bearings must be replaced. There are cracks or gaps in any of the inner ring, outer ring, rolling elements, and cage.

1. There is a break in any of the ferrule and rolling element.

2. There are obvious stuck injuries on the rolling surface, ribs and rolling elements.

3. The cage wears significantly or the rivets loose significantly.

4. There is rust on the raceway surface and rolling body, which may cause injuries.

5. There are serious indentations and scratches on the raceway surface and rolling elements.

6. There is obvious creep on the inner diameter surface of the inner ring or the outer diameter surface of the outer ring.

7. Discoloration caused by heat is obvious.

8. For bearings sealed with grease, the seal ring or dust cover is obviously damaged.

Management of NSK bearing anti-rust auxiliary materials

Cooling water mainly plays multiple roles in cooling, lubrication, cleaning, and rust prevention in NSK bearing processing. Its correct use and maintenance directly affect the surface quality of the processed parts and affect the service life of the tool.

The cooling water used can be roughly divided into three kinds of soda water, emulsified liquid and synthetic grinding liquid. Basically, the tank liquid of more than 50 tons is used for large circulation. The grinding product, grinding wheel dust, iron dust and oil stains washed down are easy Causes the deterioration and deterioration of the cooling water, causing burns and rust on the processed parts. Strengthening the scientific management of cooling water can improve its performance, ensure product quality, and reduce the cost of cooling water.

In order to ensure that the anti-rust process can be seriously implemented, the technical department has formulated specific assessment rules according to the process requirements, NSK bearings and converted the component value to evaluate the production plant.

The first-level anti-rust management personnel conducts monthly process discipline inspection on the production plant. The management of cooling water, anti-rust liquid, cleaning fluid, anti-rust oil and the corrosion rate, cleanliness and oiled packaging of finished NSK bearings are The management level of the rust prevention personnel and the inspection situation of the monitoring project are subject to a comprehensive inspection, assessment and scoring, and the assessment results are issued to the production plant. Establish a rust prevention management work network from top to bottom, so that the rust prevention work has a good management foundation.

The quality of anti-rust materials directly affects the quality of product processing. Therefore, when selecting anti-rust materials, the physical and chemical properties should be tested according to the quality requirements, and then the pilot test should be conducted after passing the test. The selected anti-rust auxiliary materials will be strictly tested according to the quality standards of different materials after entering the factory. After the NSK bearings are qualified, they can be used by the supply department.

During the use process, the anti-rust material and the prepared solution shall be tested regularly to ensure that the concentration and proportion of the solution meet the process requirements and reach the performance. The establishment of a complete material acceptance system and quality acceptance standards provides a reliable guarantee for good anti-rust management.

NSK Bearings' own factors affect the service life

The service life of NSK bearings is usually affected by two factors, material and process.

The material of the NSK bearing largely determines the service life of the NSK bearing. The metallurgical quality of the NSK bearing was the most important reason for the early failure of the rolling NSK bearing. The impact of NSK bearing materials on service life has been greatly improved after metallurgical technology has made great progress, and materials such as NSK bearing steel have appeared one after another.

In the failure analysis of NSK bearings, the proportion of NSK bearing failures caused by raw materials has dropped significantly, but the material is still an important reason for NSK bearing failures, and it is also the main limiting factor for the service life of NSK bearings.

The manufacturing process of NSK bearings is complicated, and the finished product needs to be obtained after multiple processes. Among them, the technical capabilities and quality of the forging, heat treatment, turning and grinding processes will affect the service life and application effect of NSK bearings, especially heat treatment and The grinding process is the direct cause of the failure of many NSK bearings and needs to be highly valued by the production enterprises.

Hot Tags: