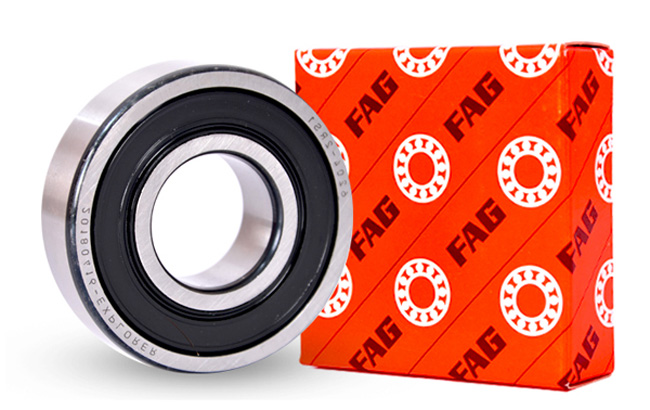

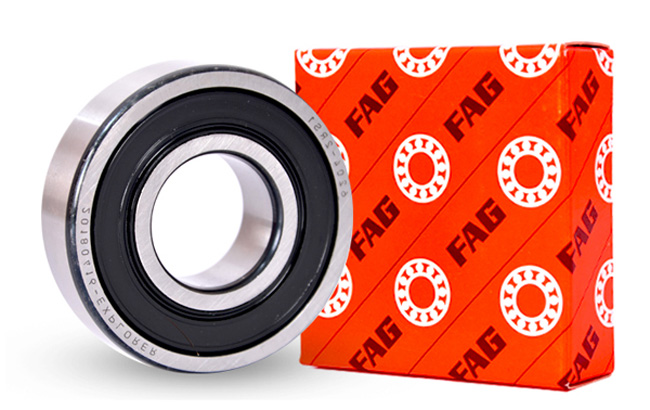

The Factors of Influencing FAG Roller Bearing Life

The factors affect the service life of FAG roller bearing are mainly the following aspects: the condition of the bearing itself, the use of the bearing, the operation of the mill, the storage of the bearing, and so on.

Bearing use is an aspect that users can subjectively control, and it is also the key to affecting bearing life. The factors that affect bearing life are infiltrated from installation to specific operations and maintenance. Installation: The quality of the roller bearing is an essential factor affecting its service life. Many failures or damage to the roller bearing in advance are related to improper assembly. The user must strictly follow the instructions when replacing the roller bearing. If it is installed too loosely or too tightly, it will cause premature damage to the roller bearing.

Application: mainly includes sealing, lubrication, and monitoring. In the application environment of high temperature, impact, heavy load, and low speed, it is difficult to form a good lubrication condition for the bearing. The harsh dust environment and impact have worsened the lubrication condition. The actual application results show that most FAG roller bearing bearings are damaged due to improper bearing lubrication. In terms of monitoring and protection: sealing pressure and taking temperature should be monitored in real-time, control logic, and interlocking should not be removed at will. When the sealing pressure and bearing temperature are found to be abnormal, stop grinding in time to prevent damage to the FAG roller bearing.

Sealing also has a significant effect on the service life of the 1211KTV FAG roller bearing. The role of the seal is to prevent the lubricant from leaking out of the bearing. At the same time, prevent external dust from entering the bearing. In a high-dust working environment, if a large amount of small hard particles enter the inside of the vertical roller bearing, it will deteriorate the working environment of the bearing, reduce the lubrication effect, and even form an indentation on the raceway surface, causing pitting or even peeling of the raceway surface. Reduce the working life of the bearings. Therefore, the selection of high-reliability sealing component is essential to improve the moving experience of the bearing. The seals at the FAG roller bearing bearings are in the form of sealed air, that is, compressed air is used to prevent the dust in the grinding chamber from entering the bearing lubricant. The sealing wind must have absolute pressure, and the clearance at the wind ring must not be too large. For tapered roller bearing, the sealing wind pressure must be above 5000Pa, and the removal of the wind ring is less than 3 ~ 5mm, ensuring that the wind speed at the wind ring is 50m / more than s, can achieve useful sealing effect.

Because 1310KTV FAG roller bearing are lubricated with oil pools, they cannot effectively take away the heat generated during the work of the bearings, and it is not easy to remove the small impurities existing in the bearings and to clean the working environment of the bearings. Therefore, the choice of lubricant is particularly essential.

Tapered roller bearing storage and improper storage of the bearing are also a factor affecting its life. If the bearing is not placed horizontally, it will change its clearance accuracy. If the packaging is not tight, the working surface of the bearing will be rusted when it is exposed to humid air, which will cause tiny pitting. In the pit, stress concentration points will occur during operation, which will cause failure and affect life.