As an important mechanical foundation, ceramic bearing has excellent performance unmatched by metal bearings. Its high temperature resistance and super strength have taken the lead in the world of new materials. Ceramic bearings are increasingly used in a wide range of applications, but ceramic ball bearings have been successfully used in industrial applications. The most commonly used are silicon nitride ceramic ball bearings. Its advantages are: high limit speed, good accuracy retention, small starting torque, high rigidity, good dry running, long life, very suitable for maintaining high precision and long time running under high speed, high temperature and corrosion and radiation conditions, Mainly used in CNC machine tools and high-speed precision machinery, such as high-speed electric spindle bearings, machine tool spindle bearings, dental drill bearings, instrument bearings, computer hard drive bearings, etc. In addition, the hardness of silicon nitride ceramic is 1 times higher than that of bearing steel, and the elastic modulus is about 1/3 higher. Under the same load condition, the elastic deformation of silicon nitride ceramic is small. Therefore, the machine tool spindle using ceramic ball bearings has good running accuracy.

SKF bearings is committed to research and provide solutions for wind turbines. This is very prominent in the field of imported bearings. Because of the high precision and high quality of SKF imported bearings, it has always been welcomed by the wind turbine industry.

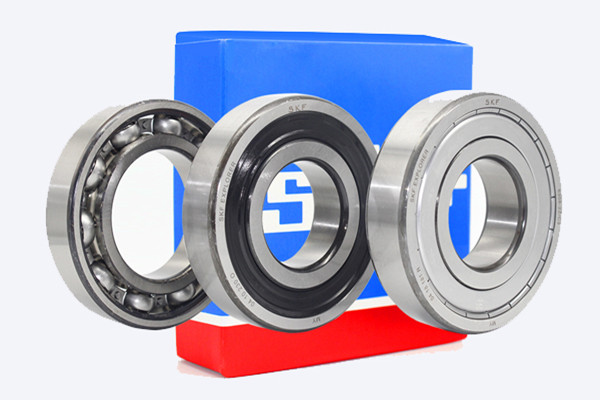

Oversized SKF ceramic bearings for wind turbines

Extra large SKF ceramic bearings specially designed and developed for large wind turbines can isolate current. These bearings are unique in design. The bearing rings are made of steel bearing products. The balls are made of bearing grade silicon nitride (Si3N4), which has high hardness and low density.

Advantage

(1) Improve the availability and operational safety of wind turbines by avoiding manual lubrication;

(2) Prolong the service life of wind turbines;

(3) Extended maintenance interval;

(4) Reduce operating costs and lubricant costs;

(5) Reduce the risk of lubrication-related failures;

(6) Quickly determine the fault / broken supply line or short circuit;

(7) Reduce environmental impact by avoiding excessive lubrication;

(8) Monitoring lubrication status via network.

In addition to excellent electrical insulation, the large SKF ceramic bearings deep groove ball bearings design fully utilizes the role of lubricant, ensuring long-term performance even in the case of poor lubrication.

As a result, life cycle costs and total operating costs are reduced by minimizing downtime and maintenance costs.

This solution requires less maintenance, but provides high reliability and excellent performance, which can increase your large wind turbine output and profitability.

Improving reliability can also provide competitiveness and survival for the entire industry without relying on political help.

Automatic lubrication system for wind turbine

In order to simplify maintenance and reduce environmental impact, SKF WindLub centralized lubrication system provides all rotating equipment at the right place at the right time with the precise dosage of suitable lubricant. SKF WindLub helps improve the reliability and availability of wind turbines. The system also helps to extend the life of wind turbines and reduce operating and lubricant costs. In addition, SKF WindLub minimizes environmental impact by avoiding excessive lubrication.

SKF WindLub can be easily integrated with SKF WindCon to further simplify maintenance and enhance reliability. This combination provides the operator with a complete overview of the lubrication system.

Benefits

(1) Improve reliability and enhance sustainability;

(2) Reduce life cycle costs and total operating costs;

(3) Eliminates premature bearing failure caused by galvanic wear;

(4) Maximize the effect of lubricant;

(5) Reliable operation even under poor lubrication conditions;

(6) Standard bearing dimensions;

(7) Easy to upgrade existing wind turbines.

Hot Tags: