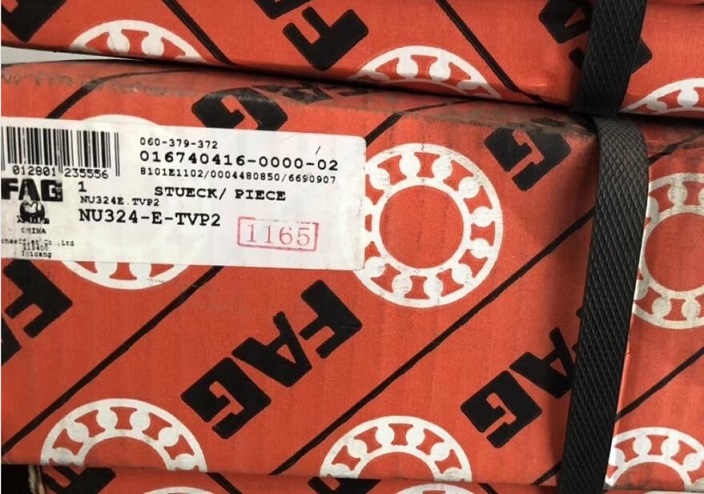

FAG Bearing was first affiliated with Fisher ( FAG ) Co., Ltd., and was later acquired by the current INA Bearing Group, now referred to as Schaeffler Group. The products of the Schaeffler Group are applied to all moving objects to maximize their professional expertise.With good bearing reputation, reputation and strength, Shanghai FAG bearings have been pushed to the peak of imported bearings in a short period of time , and will continue for the long term. Schaeffler built 170 branches in 49 countries by virtue of its strength , forming a one-stop production chain test, which lays a solid backing for the development, research and manufacture of bearings.Its 16 R & D bases and about 6,000 R & D personnel in various countries in the world have become one of the four major German innovation companies with an average annual registration of 2,100 patents and a total of 20,000 valid patents, all of which highlight its brilliant development momentum in recent years.A series of progressively silent talks about the rapid development of mechanical technology since the 21st century, and the bearings that are inseparable from mechanical technology take off. Bearing FAG NU324-E-TVP2 online , pls click here :

When FAG Bearings how to do burn occurs

During the operation of FAG bearings, it is inevitable that they will be used improperly and the temperature is too high, which will cause the bearing to burn out. The so-called cracking of the burnout condition in Saskatchewan refers to the fact that the needle bearing exerts a musical impact or excessive load on some of the ribs or roller angles of the raceway wheels and cracks slightly. The element that presents this kind of situation is that the needle bearing is impacted when it is in the equipment. Poor use such as drop. The load is too large.

The corresponding method is to improve the equipment method (select hot pack, use the appropriate thing clip). The needle roller bearing equipment is in place so that the rib is supported. Correct the load conditions.

The needle roller bearing presents the situation when it is stuck:

The so-called seizure is the appearance damage that occurs due to some minor burns of the needle bearing in the sliding surface injury. Linear scratches on the chute surface and rolling surface. The cycloidal flaw on the roller end surface is close to the collar surface of the roller end surface.

The elements of the needle roller bearing presenting the appearance of the injury:

Excessive load, excessive preload. Poor smooth. Foreign bodies bite in. The deflection of the inner and outer rings, the deflection of the shaft. The precision of the shaft and bearing box is poor.

The method of needle roller bearing showing the appearance of stuck:

View the size of the load. Preload should be appropriate. The retained austenite increases in the overheating arrangement, and the dimensional stability decreases. Because the quenching arrangement is overheated, the crystals of the steel are coarse, which will cause the resistance of the parts to decrease and the life of the bearing to decrease. Severe overheating may even cause quenching cracks. Improve smoothing agents and smoothing methods. Check the accuracy of the shaft and bearing box.

The so-called bearing damage situation refers to: the bearing's race wheel, rolling body, and holding frame heat rapidly during rotation until they become discolored, softened, welded, and damaged.

The second may be excessive load (excessive preload). The speed is too large. The play is too small. Water or other foreign objects invaded. If the above two conditions are not the same, it means that the accuracy of the shaft and bearing housing is poor, and the shaft deflection is large. Seeing this, I think we all want to know how to deal with it. First of all, choosing the right bearing smoothing agent, we must study the smoothing agent and the smoothing method, and its dosage .

View accuracy of shaft and bearing housing

From the FAG import bearing parts can be rough opening investigations into the microscopic arrangement after quenching overheating. But to determine the degree of overheating, it is necessary to investigate the microscopic arrangement. If coarse needle-shaped martensite appears in the quenching arrangement of GCr15 steel, it is quenching and overheating arrangement. The component may be the overall overheating caused by too high quenching heating temperature or too long heating and holding time; the low-carbon zone between the two belts constitutes some martensite needles and the FAG bearing constitutes some overheating.

The metallurgical quality of FAG bearings used to be the main factor affecting the early failure of rolling bearings. It may also be because the initial arrangement of the ribbon carbide is severe, and the quality of the original data has been improved as the metallurgical skills (such as vacuum degassing of bearing steel) progress. But it is still one of the main factors affecting bearing failure.

Whether the material selection is proper is still an essential element to consider for bearing failure analysis:

The manufacture of bearings usually requires multiple processing steps such as casting, heat treatment, turning, grinding and assembly. The advancement, rationality and stability of each processing technology will also affect the bearing life. The impact resistance function is reduced, during the heat treatment and grinding processes that affect the quality of the bearing of the product, the proportion of the original data quality elements in the analysis of bearing failure has now declined significantly, and it is usually more directly related to the failure of the bearing. The research on the appearance transformation layer of the bearing operation in recent years indicates that it is based on a lot of set data, analysis data and failure methods, and the grinding technology is closely related to the quality of the bearing appearance .

The main tasks of FAG bearing life analysis:

In order to put forward targeted improvement measures to prevent sudden early failure of bearing attacks.

If the quenching temperature is low or the cooling is not good, the micro-arrangement will cause a torticite arrangement that exceeds the rules. The service life of the extended bearing will be the main factor that constitutes the bearing failure. Abrasiveness drops sharply, affecting FAG bearing life. Bearing NU 312-E-XL-JP3 online , pls click here :

FAG bearing parts caused by internal stress during quenching and cooling process is called quenching crack. The elements that constitute such cracks are: because the quenching heating temperature is too high or the cooling is too rapid, the thermal stress and the arrangement stress when the metal mass volume changes are greater than the steel's crack resistance; the original defects of the appearance of the operation (such as micro cracks or scratches on the surface) Traces) or internal defects of the steel (such as slag inclusions, severe non-metallic inclusions, white spots, shrinkage cavities, etc.) severe external decarburization and carbide segregation; the presence of internal stress is the main factor that constitutes quenching cracks. The fracture is straight, the quenching crack is deep and slender, the cold punching stress formed by the previous process is too large, casting folds, deep turning tool marks, sharp corners of the oil groove, etc. In summary, the elements that constitute the quenching crack may be one or more of the above elements, and the fracture surface has no oxidation color. The stress concentration is formed during quenching; the part is not tempered enough or not tempered in time after quenching; it is usually a longitudinal straight crack or ring crack on the bearing ring; the shape of the bearing steel ball is S -shaped and T -shaped Or ring type. The quenching crack arrangement is characterized by the absence of decarburization on both sides of the crack, which is significantly different from casting cracks and data cracks.

The real role of FAG bearings in life

The real effect of bearings in life can be imagined. We can't ignore it. The service life of imported bearings is the performance of the maximum utilization rate of bearings. In the world of imported bearings, there are many types of bearings. The motor is the power of the machinery. This is what we all know. So do we know what is the main component of the motor? It is an imported bearing. Do we know what is the main effect of the motor? It is the bearing. We may think that a What impact will a small bearing have on the motor? If you think wrong, there will be no bearings in the motor, so there is no way for the motor to work. If you click there is no way to work normally, then your machinery will not work properly. It will delay our normal production and will delay our normal benefits, so the bearing is the most important for the motor, we should not ignore this will cause us a lot of trouble, once the motor can not be used then There is no way for all mechanical equipment to work, but it also brings us a lot of losses, so we must not ignore this. Let us use very good bearings to help us do more things, so that our efficiency has greatly improved. This is what we want to see. Thrust bearings are mainly used in automobile clutches or reducers. We need to find each one. The characteristics of bearings use these characteristics to bring us greater benefits. If you do n’t know much about bearings, but now you want to understand imported bearings, then you can contact us. We will help you understand the characteristics of bearings and help you very well. Use them to give them greater benefits.

How to repair FAG bearing after cleaning and wear

No matter what, it will wear a little after use .

FAG bearings are the key equipment of the ultrasonic cleaning machine system. Because the mission conditions of the imported bearings of the cleaning machine are extremely harsh, they must operate continuously under the conditions of shock, vibration and overload, and the service life is required to be more than 15 years . The reliability is extremely high. Therefore, the use of ultrasonic cleaners puts forward higher requirements for the planning and production of bearings.

The correction position is accurate and sensitive, the correction amount can control the accuracy, and it can be corrected without crashing on site. After the correction, the tool grinding skills can be accurately restored to the size. The cleaning machine is used to grind cement, coal and other industrial materials such as construction, chemical industry, ceramics, etc. It has a series of advantages such as small size, light weight, small footprint, low power consumption, energy saving agreement reached more than 30% , and long service life.

During the correction process, FAG bearings are always at room temperature, no internal stress occurs, no thermal deformation, cracks, annealing, softening appearance, and no potential impact of breakage or cracking. High connection strength, no drop appearance, no hard spots, high surface finish, adjustable hardness. Suitable for low carbon steel and low carbon alloy steel, medium carbon steel and medium carbon alloy steel, high carbon steel and high carbon alloy steel, high strength alloy steel, stainless steel, cast steel, cast iron, copper and copper alloy, aluminum and aluminum alloy , Zinc and zinc alloys, chromium, nickel, chromium-nickel steel and unknown materials are corrected.

Solutions to Overheating of Motor FAG Bearings

1.FAG bearing is damaged. Solution: Replace.

2.There is too little lubricating oil in the sliding FAG bearing, there are impurities or the oil ring is stuck. Solution: add oil, replace with new oil, repair or replace the oil ring.

3.Rolling FAG imported bearing grease is too little, too much or there are impurities such as iron filings. Solution: The capacity of FAG imported bearing grease should not exceed 70 % of the total volume. Those with impurities should be replaced.

4.FAG imported bearing and end cover are too tight or too loose. Solution: When the bearing is too tight, FAG imported bearing room is processed , and when it is too loose, steel sleeve is inserted in the end cover.

5.The belt is too tight or the coupling is poorly assembled. Solution: Adjust the belt tension and correct the coupling.

6.The two ends of the motor cover or FAG imported bearing cover are poorly assembled. Solution: Install the end cover or FAG bearing cover stop and tighten it.

7.The shaft and FAG imported bearings are too tight or too loose. Solution: re-grind when it is too tight, and insert the shaft when it is too loose.

Hot Tags: