The peeling damage of the NSK bearing means that when the bearing rotates under load, the raceway surface or rolling body surface of the inner and outer rings exhibits scaly peeling due to rolling fatigue.

The causes of bearing peeling damage are: excessive load on the bearing; poor lubrication of the bearing or selection of inappropriate lubricants; poor installation, torque load, foreign body intrusion or water ingress; poor precision of the bearing box is too low, and the rigidity of the bearing box is uneven The deflection is large; rust, erosion points, scratches and indentation, etc.

Precautions: Check the size of NSK bearing load and the bearing used in the research again; select the appropriate lubricant to lubricate the bearing and improve the lubrication method; improve the installation method, strictly follow the installation procedure for installation, improve the sealing device, and shut down Anti-rust measures; check the accuracy of the shaft and bearing box, select bearings with high accuracy grade; check the bearing clearance to make it appropriate.

The vibration of the NSK bearing has a significant effect on the failure of the bearing. For example: peeling, indentation, rust, cracks, wear, etc. will be reflected in the bearing vibration detection. So by using special bearing vibration measurement devices (frequency analyzer and vibrometer, etc. ) The size of the vibration can be measured. The frequency distribution can be used to infer the details of the abnormal vibration. The measured values are different due to the use premise of the bearing or the installation position of the sensor, etc. Therefore, it is necessary to analyze and compare the measured values of each machine in advance to determine and judge scale.

At present, the equipment that uses precision bearings is becoming more and more refined, and the grease used in NSK bearings must have the following functions:

(1) With the same operating life as the bearing, the maintenance cycle should be delayed as much as possible, the downtime should be shortened, and the labor productivity can be improved.

(2) At a high speed of dn>5×105, it is necessary to ensure that the temperature rise of the motor is low and oil is not dumped, thereby reducing power consumption and protecting the motor.

(3) Its scalar content control is under the inevitable standard, and the pollution of the equipment noise to the situation is minimized.

(4) Under the premise of ultra-low temperature work, it guarantees the flexibility of starting and running of bearings, common problems of NSK bearings. Guaranteed minimum output power.

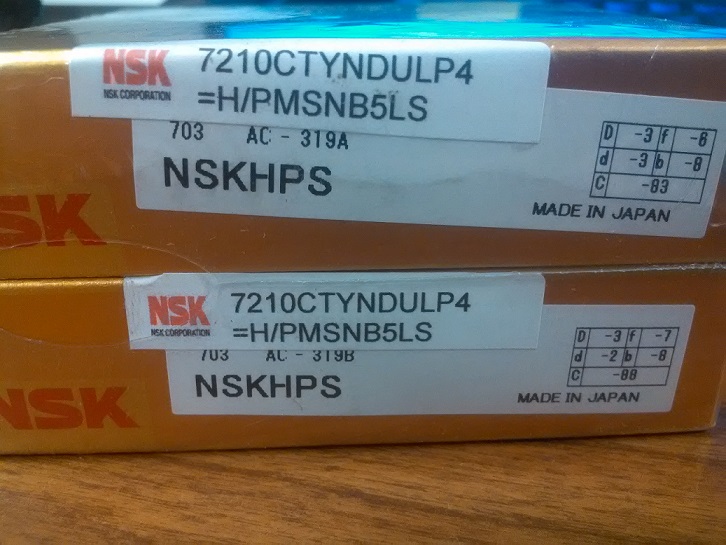

The cleaning of the removed NSK bearings is divided into rough cleaning and fine cleaning, and they are placed in the container, and the metal mesh pad is placed first so that the bearing does not directly contact the dirt of the container. During rough cleaning, if the bearing is rotated with dirt, it will damage the rolling surface of the bearing, and it should be noted. In the coarse cleaning oil, use a brush to remove smooth grease and adhesions. After roughly cleaning, transfer to fine washing. NSK 7210CTYNDULP4 bearings online , if you need , pls click here :

The important relationship between the cleanliness of NSK bearings and heat

Under ordinary conditions, the amount of grease filled in NSK bearings has always exceeded the practical requirements for direct intervention in lubrication, filling the cavity on the frame and the bearing cover of the rolling mill, and forming a contour around the periphery of the rolling body. During this process, because of the resistance of excess grease, the bearing temperature quickly rises. Although most of the excess grease is squeezed out at the beginning of the operation, the grease squeezed on the accessories of the raceway may still be transferred into the raceway by the rolling element.

In the early stages of rolling mill bearings, most of the grease is quickly squeezed out of the raceway (less than a minute), and the accumulated grease is discharged in small quantities one after another following the bearing migration transformation. At this time, the temperature of the nsk bearing continues to rise until all the excess grease is discharged. It can be called the running-in phase of the grease. Depending on the quality and the amount of grease in the bearing structure of the rolling mill, this period may last more than ten Minutes, or even hours.

1. Impact on NSK bearing life:

The cleanliness of NSK bearings has a considerable impact on bearing life. Bearing companies have conducted special tests for this purpose, and the result is that the difference is several times or even tens of times. The higher the cleanliness of the bearing, the longer the life. The tests of others showed that the lubricating oil of different cleanliness has a great influence on the life of the ball bearing. Therefore, improving the cleanliness of the lubricating oil can extend the life of the rolling mill bearings. In addition, if the lubricating particles contained in the lubricating oil are controlled below 10um, the bearing life will also increase several times.

2. Impact on vibration and noise:

Effect on vibration: The NSK bearing test results show that the cleanliness seriously affects the vibration level of the rolling mill bearings, especially the high frequency band vibration is more significant. Bearings with high cleanliness have low vibration velocity values, especially in high frequency bands.

3. Effect on lubrication performance:

The decrease in the cleanliness of NSK bearings not only affects the formation of lubricating oil films, but also causes the deterioration of the grease and accelerates its aging, thereby affecting the decrease in the lubricating performance of the grease.

NSK double row deep groove ball bearing friction maintenance skills

The function of the double row deep groove ball bearing is to make the stationary ring and the rotating ring of the NSK bearing are consolidated with the stationary part (usually the bearing seat) and the rotating part (usually the shaft) of the installation site, so as to achieve the rotation state The basic task of transferring loads and defining the position of a kinematic system relative to a stationary system.

On the shaft and in the bearing housing, NSK bearings are required to fix their positions in three directions: radial, axial and tangential directions. Radial and tangential positioning is achieved by tight fitting of double row deep groove ball bearing rings. Axial positioning is only used in a few cases; tight fitting is generally used, such as end caps and retaining rings Limit the axial position to the clearance range.

The performance of double row deep groove ball bearings to prevent adhesion and boundary lubrication when the shaft diameter is directly in contact with the bush. The material factors that affect the friction compatibility of the friction pair are:

(1) The difficulty of forming alloys as secondary materials in metallurgy.

(2) The affinity of materials and lubricants.

(3) The friction factor of the secondary material in the non-lubricated state.

(4) The microstructure of the material.

(5) Thermal conductivity of the material.

(6) The size of the surface energy of the material and the characteristics of the oxide film.

Use the oil pump to shoot high-pressure oil into the bearing through the nozzle, and the oil injected into the NSK bearing flows into the oil groove through the other end of the bearing. When the bearing rotates at a high speed, the rolling elements and the cage also form a flow of surrounding air at a relatively high rotation speed. It is difficult to send the lubricating oil to the NSK bearing by the general lubrication method. At this time, the lubricating oil must be sprayed by high pressure Sprayed into double row deep groove ball bearings, the position of the nozzle should be placed between the inner ring and the center of the cage.

Hot Tags: