The raceway sound of INA bearings and its control method The raceway sound is a smooth and continuous sound produced by the rolling body rolling on the raceway surface when the bearing is running. It is a unique basic sound that occurs in all bearings. The general bearing sound is the raceway sound plus other sounds. The greater the rigidity of the bearing housing, the lower the sound pressure level of the raceway sound. If the radial clearance is too small, the sound pressure level and main frequency of the raceway sound will increase sharply as the radial clearance decreases.

INA bearing fatigue failure is a surface form of failure, mainly manifested as fatigue crack initiation, propagation and fracture process, the metal caused by the long-term impact of the load failure generated under alternation.Cracks in two ways

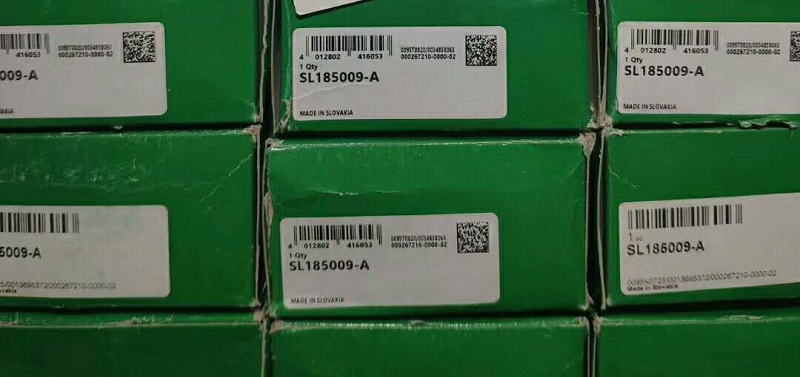

From the bearing surface, it is still from the cracks in the surface layer, these two goals (part carburization, quenching and other surface heat treatment, if there is uneven hardness, structure, and non-uniform internal stress and other disadvantages, then the contact stress Generally from the effect of producing the opposite underground cracks, if the surface quality of the parts is poor, there is a defect (oxidation, decarburization), poor friction or lubrication, cracks from the surface. ERIC BEARING LTD have INA SL185009A bearing in stock , see below photos , if you need , pls contact us freely .

The methods to control the raceway sound are: select low-noise bearings, that is, INA bearings with very low waviness, and carefully choose the conditions of use. The sound of the raceway often affects the noise of the whole machine. Reducing the sound of the raceway can reduce the noise of the whole machine.

1. The bearing raceway and the sound control method are INA bearings during operation. On a continuously rolling sliding surface, there are printed distinctive ball foundations. In other words, the overall sound of the roller bearing with other sounds. The ball rolls irregularly, above the frequency of 1000Hz, it will not change the main frequency of the speed change, but the overall speed rapidly increases the sound pressure level.

It affects the raceway. The sound pressure level of the raceway is increased by decreasing the viscosity. For a small roller bearing, the sound pressure level of the medium viscosity increase is soundly related to 20 square millimeters/second or more, decreasing and increasing. The greater the INA bearing stiffness, the lower the sound pressure level of the entire runway. If the radial clearance is too small, the total sound pressure level of the angular contact ball bearing and the reduction of the main frequency will greatly increase the radial clearance. Control of raceway sound: a small selection of carefully selected conditions for use with low-noise bearing pulsation methods.

2. The pure radial load of ball and control ball bearings or bearings is influenced by the large listening mode. At low speeds, due to the centrifugal force driving on a non-small area load rolling will affect the cage or raceway and noise. However, as the speed increases, the noise will disappear.

The impact on the method to control its working capital includes: appropriately reducing the radial clearance, using a rational structure is the flexibility of the INA bearing cage.

3. Bearing discordant noise and sound-controlled shock bearings, INA bearings each of his harsh metal friction opportunities, mainly in fat-lubricated bearings in larger models, while oil based on degradation performance is more likely to appear Grease, in any lubricant.

In addition, it is more likely to occur in winter, when pure radial loads, radial clearances and special occasions are vulnerable, and at a specific speed, high in different sizes, the second will also produce continuous intermittency. The specific treatment method of the outer ring raceway to prevent the occurrence of dissonant sounds, if any, you can choose this INA bearing, or appropriately reduce the internal clearance of the bearing, excellent performance and bearing grease and matching parts to improve rigidity.

INA plane bearing use and installation process considerations

It is best not to use worn or damaged INA bearings in your vehicle, because this may bring you unsafe factors during driving, and in serious cases will cause life safety injuries. Therefore, you must pay attention to the use and installation of flat bearings:

1. How to define the position of the shaft, including radial and axial positions is the first issue to be considered.

Generally, the shaft adopts a double support structure. The radial position of the shaft is jointly defined by two supports. Each support should have a flat bearing that plays a radial positioning role. The axial position can be limited by two supports to limit the axial displacement in one direction or one support to limit the axial displacement in two directions. In general, different axial positioning methods can obtain different running accuracy. Therefore, when designing the support structure, the specific scheme of axial positioning should be selected according to the running accuracy and working conditions of the INA shaft.

2. In the case of bearing radial load and axial load at the same time, the bearings are often installed in pairs.

There are three arrangements for plane bearing installation in pairs. The relative installation of the wide end surfaces of the two bearing outer rings is called back-to-back installation. The two support force action points fall outside the support span. This arrangement is due to the large support span, good rigidity when the shaft is cantilevered, and the inner and outer rings show a tendency to disengage when the shaft is heated and extended, so the shaft will not be stuck, so it is widely used. However, if pre-tensioning is used, the amount of pre-tensioning will be reduced when the shaft is heated.

The relative installation of the narrow end surfaces of the two bearing outer rings is called face-to-face installation. The force action points of the two supports fall within the support span. This arrangement is simple in structure, easy to assemble and disassemble, and debug, so it is also widely used. It is mainly used for short shafts and low temperature rise, but it must be kept with spare clearance. The axial clearance should not be too large, too large will reduce the running accuracy of the shaft. When the axial load is large and multiple INA bearings are required to bear at the same time, the series connection method where the outer ring width and the narrow surface of the bearing are relatively installed is often used. Each bearing force action point falls on the same side of the bearing, so it is called co-arrangement and series connection.

When using this arrangement, attention should be paid to the structure and manufacturing to ensure that each imported bearing can withstand the load as uniformly as possible.

3. During the operation of the machine, the temperature of the main shaft or the transmission shaft is generally higher than the temperature of the adjacent parts, so the shaft will expand thermally.

In order to keep the rotation of the shaft flexible, in the design of the supporting structure, while meeting the requirements of the axial positioning accuracy, the requirement of the shaft to freely expand and contract under heat must also be considered. The methods of axial positioning and axial expansion and contraction are corresponding.

4. The bearing clearance is adjusted to control the running accuracy of the shaft.

The axial position adjustment of the shaft is to meet the special requirements of some meshing drives. For example, in the worm drive, the worm axis must fall in the middle plane of the worm wheel to ensure proper meshing. Therefore, it is required that the worm wheel shaft can adjust its position in the axial direction. In the bevel gear transmission, the apex of the pitch cones of the two bevel gears must coincide, which requires that both bevel gear shafts can be adjusted axially.

Hot Tags: