Nippon Seiko Co., Ltd. (Headquarters: Shinagawa-ku, Tokyo, Representative: Representative Executive Officer Toshihiro Uchiyama, hereinafter referred to as NSK) has successfully developed "Insulated Bearings for Inverter Motors for General Industrial Machinery". In order to meet the needs of energy saving, the application of variable frequency motors in various fields is gradually expanding. This product can be applied to variable frequency motors mounted on general industrial machinery such as pumps, compressors, and fans, and has excellent performance.

Improving the insulation performance of bearings for inverter motors is one of NSK's research topics. It is expected that this product will achieve its annual sales target of 1 billion yen in 2020.

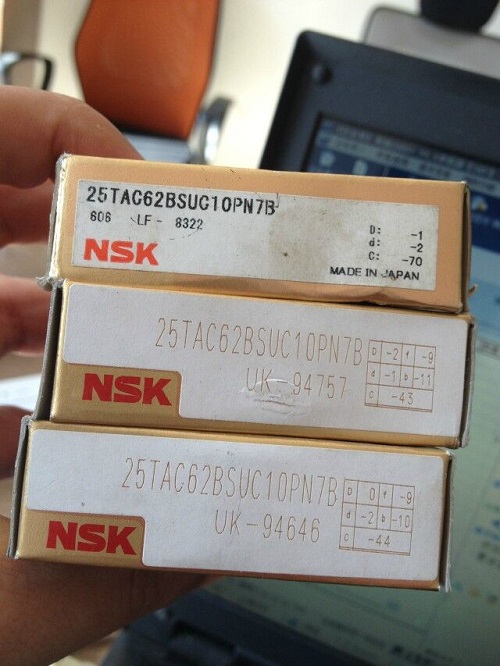

In order to achieve energy saving and high efficiency, frequency conversion control technology is increasingly used in general industrial machinery motors. Corresponding to this, a kind of bearing damage known as electro-erosion phenomenon occurs from time to time. NSK 25TAC62BSUC10PN7B bearings online , pls click here :

In order to avoid the occurrence of this galvanic corrosion phenomenon, ceramic balls that can block the passage of current can be used in the bearing, but its productivity is a big problem. In addition, although the insulated bearing housing can be used in the motor, it requires special supporting parts and special assembly methods, which is also a big problem. For this reason, NSK has developed a new type of insulated bearings with high production efficiency and good versatility that are easily interchangeable with ordinary bearings.

Electric corrosion: When a current flows through the contact part of the ring and the roller of the bearing in operation, the thinner part of the grease film will be broken down, causing local melting and unevenness on the contact surface.

Features

1. High insulation performance

The new alumina-based ceramic material with excellent production performance is sprayed on the surface of the outer ring, and with the most suitable additives, the insulation performance is increased by more than 10 times, which can effectively prevent the occurrence of bearing galvanic corrosion.

2. Long durability

By optimizing the bearing design, the impact resistance of the coating is increased by more than 3 times.

The best ceramic coating material is used to achieve good heat dissipation of this product.

Product effect

Improve the reliability of general industrial machinery motors and expand the application fields of variable frequency motors.

Hot Tags: