Due to its own quality and external conditions, the bearing capacity, rotation accuracy and wear resistance of INA bearings will change during use. When the performance index of INA bearings is lower than the use requirements and cannot work normally, INA bearings occur After failure or even failure, once the INA bearing fails and other unexpected situations, the machine and equipment will stop, and various abnormal phenomena such as loss of function will occur. Therefore, it is necessary to find out the cause of the occurrence in a short period of time and take corresponding measures.

In order to enable INA bearings to maintain proper performance and long-term use under good conditions. INA bearings must be inspected and maintained. Inspection and maintenance are important to prevent malfunctions. In operation, focus on the rolling noise of INA bearings , Vibration, temperature and lubricants. INA RAE30-NPP bearings online , pls contact ERIC BEARING LTD if you need :

Vibration of INA bearings

The vibration of the INA bearing has a significant effect on the failure of the INA bearing. For example: peeling, indentation, corrosion, cracks, wear, etc. will be reflected in the INA bearing vibration test, so by using a special INA bearing vibration measurement device (frequency analyzer And vibration meter, etc.) can measure the magnitude of vibration, and the specific conditions of abnormal vibration can be inferred from the frequency distribution.The measured values vary depending on the use conditions of the INA bearing or the installation position of the sensor, etc. After analyzing and comparing the measured values, determine the judgment standard.

INA bearing temperature

Generally, the temperature of the INA bearing gradually increases with the operation and reaches a stable state after 1 to 2 hours. The normal temperature of the INA bearing varies according to the heat capacity, heat dissipation, rotation speed and load of the machine. If lubrication and installation are not suitable, The temperature of the INA bearing will rise sharply, and abnormally high temperature will appear.At this time, you must stop and take the necessary precautions.

Lubricant

Lubrication has an important effect on the fatigue life and friction, wear, temperature rise, vibration, etc. of rolling INA bearings. Without normal lubrication, INA bearings cannot work. Analysis of the damage causes of INA bearings shows that about 40% of INA bearing damages are related to Poor lubrication. Therefore, good lubrication of INA bearings is an effective measure to reduce friction and wear of INA bearings. In addition, the lubrication of INA bearings also plays a role in heat dissipation, rust prevention, sealing, and cushioning impact. It cannot be expired, and the selection must be correct.

Corrosion, black skin, and pitting, the latter two are defects that are easy to store moisture and dirt, and are most likely to develop into rust. Corrosion is a source of pollution that leads to poor installation, early wear and fatigue. Severe corrosion will make INA bearings scrapped.

The quality of the riveting or welding of the cage, mainly to observe whether the rivet head is misaligned, skewed, slack, lack of meat or "double eyelid", whether the welding position is correct, whether the welding point is too large or too small, whether it is not welded well or over welded Causes the phenomenon of jamming the rolling body, whether the quality of the pressure slope, edge trimming, caulking and chiseling of certain cages is guaranteed, and whether the rolling bodies can fall out of the cage and can rotate freely. If these points are not satisfactory, the small As a result, the noise and rotation accuracy of the INA bearings are reduced, and the cage may fall apart, causing mechanical failure or accidents.

For the role of relative axial displacement between the fixed shaft and the bearing box, the other side is called the free side, which only bears radial load, and the axial direction can be relatively moved, so as to solve the problem of the shaft due to temperature changes The expansion and contraction problems and the spacing error of installing INA bearings.

For fixed-side INA bearings, you need to select the INA bearings that can use the rolling surface to move in the axial direction (such as cylindrical roller bearings) or move to the assembly surface (such as radial ball INA bearings). On relatively short shafts, when the fixed side is free from the free side, bearings that only move axially in one direction (such as centripetal thrust ball INA bearings) are used.

Install the INA bearing housing on the housing, if there is grease filling hole, it must be aligned with the position. Tighten the INA bearing housing with the tightening bolts coated with anti-loosening glue; tighten the eccentric block tightening bolts, turn the adjustable eccentric block to the angle position before removal and tighten the tightening bolts. After the above assembly is completed, the rotating shaft should have a certain axial series.

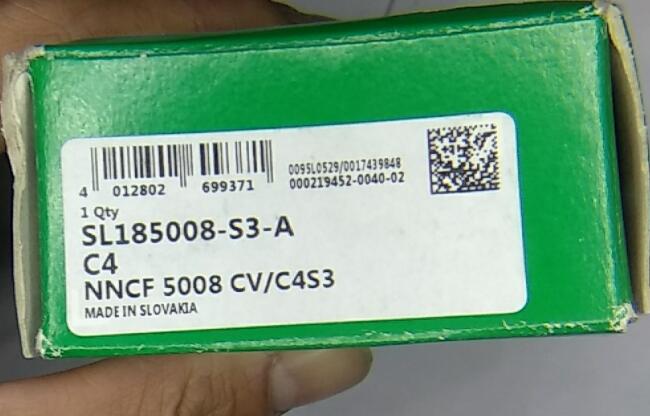

The maintenance of bearing disassembly needs to be performed better when it is cleaned. It also records the appearance and confirms the effect of the remaining amount of lubricant. It can be used as a cleaning agent for sampling and inspection. Gasoline and kerosene are generally used. The removed bearing is divided into coarse cleaning and fine cleaning, and placed in the container separately, first put the bottom of the metal mesh pad, so that the INA bearing does not directly contact the dirt of the container. During rough cleaning, if the bearing is rotated with dirt, it will damage the rolling surface of the bearing, so care should be taken. In the coarse cleaning oil, use a brush to remove grease and adhesions. After it is roughly clean, transfer to fine washing. Fine washing is to carefully clean the INA bearings while rotating in the cleaning oil. In addition, the cleaning oil should also be kept clean. INA SL185008 bearings online , pls contact ERIC BEARING LTD if you need :

The so-called INA bearing burn damage state refers to: the raceway wheel, rolling body and cage of the INA bearing rapidly heat up during rotation until they become discolored, softened, welded, and damaged.

The main cause of INA bearing burns is due to the poor lubrication of INA imported bearings. Irregular lubricants may be used, or too much or too little lubricant is incorrect. The second may be excessive load (excessive preload). The speed is too large. The play is too small. Water or other foreign objects invaded. If neither of the above two cases is true, then the shaft and INA bearing housing have poor accuracy and the shaft has a large deflection. Seeing this, I think everyone would like to know the solution. First of all, we must study the lubricants and lubrication methods, choose the right INA bearing lubricant, and its amount, and correct the choice of INA bearings. Research should cooperate, INA bearing clearance and preload, and improve the sealing device. Check the accuracy of the shaft and INA bearing housing.

How to properly disassemble and replace INA bearings

Disassembly of INA bearing outer ring

To disassemble the interference fit outer ring, set several screws for the outer ring to squeeze the screw on the circumference of the housing in advance, and tighten the screw on one side while disassembling. These screw holes are usually covered with blind plugs, tapered roller INA bearings, and other separate INA bearings. Several cutouts are provided on the housing shoulders. Use pads to remove with a press or gently tap to remove.

Disassembly of cylindrical bore INA bearing in INA bearing

The disassembly of the inner ring can be easily pulled out with a pressure machine. At this time, pay attention to the inner ring to withstand its pulling force. The hydraulic method is used to dismantle the inner ring of large INA bearings. Oil pressure is applied through the oil hole provided on the shaft to make it easy to pull out. INA bearings with a large width are used in combination with the drawing method and the disassembly operation. The induction heating method can be used to remove the inner ring of NU and NJ cylindrical roller INA bearings. The method of heating the local area in a short time to make the inner ring expand and pull.

Disassembly of tapered bore bearings in INA bearings

Disassemble the relatively small INA bearing with adapter sleeve, support the inner ring with a block fastened on the shaft, turn the nut back several times, and use a block to hit the hammer to remove it. Large bearings can be easily disassembled by hydraulic pressure. The oil is pressurized in the oil hole on the tapered shaft to expand the inner ring and disassemble the INA bearing. During operation, there is a possibility that the INA bearing may suddenly come out. It is better to use the nut as a stopper.

The specific judgment method of whether the INA bearing should be reported for repair, that is, the specific judgment method of the INA bearing has been fully utilized and the near-breakage occurs is as follows:

1. Use the INA bearing working condition monitoring instrument, such as ferrometer or SPM or I-ID? 1 type INA bearing working condition monitoring instrument to judge the INA bearing working condition and decide when the INA bearing should be repaired It is also a more reliable method. For example, when using the HD? 1 instrument, when the pointer approaches the danger zone from the warning zone, and the pointer does not return after taking measures such as improved lubrication, it can be determined that it is the problem of the INA bearing itself. At the time, the INA bearing will be reported for repair. Exactly how far from the danger zone to start repairing can be adjusted by experience. With such an instrument, it is possible to make full use of the working potential of INA bearings, report INA bearings for repair in time, and avoid failures, which is economical.

2. Use simple tools to monitor the occasions where the above-mentioned instruments are not available. Of course, it can also be modified with a medical stethoscope.

The normal INA bearing operation sound should be uniform, smooth and non-piercing sound, while the abnormal INA bearing operation sound has various intermittent, impact or harsh sounds. First of all, you must get used to the normal bearing running sound, and then you can grasp the abnormal running sound of the INA bearing, and then through the accumulation of practical experience, you can further analyze what kind of abnormal sound corresponds to what kind of INA bearing is abnormal. phenomenon. There are many types of abnormal sounds of INA bearings, which are difficult to tell, mainly relying on experience accumulation.

Hot Tags: